Martian Micro Research Facility

The Martian Micro Research Facility is a modular, zero-waste industrial complex designed for autonomous operation, long-term reuse and minimal human intervention.

The Research Facility

The Martian Micro Research Facility is the central operational site for developing, testing and operating zero-waste electronic systems.

Internally, the facility is identified as MMRF-A01. The designation is used for documentation, system addressing and internal coordination.

The facility is optimized for autonomous systems, with most tasks handled by android systems, drones and automated processes.

Why the Facility Is Elevated

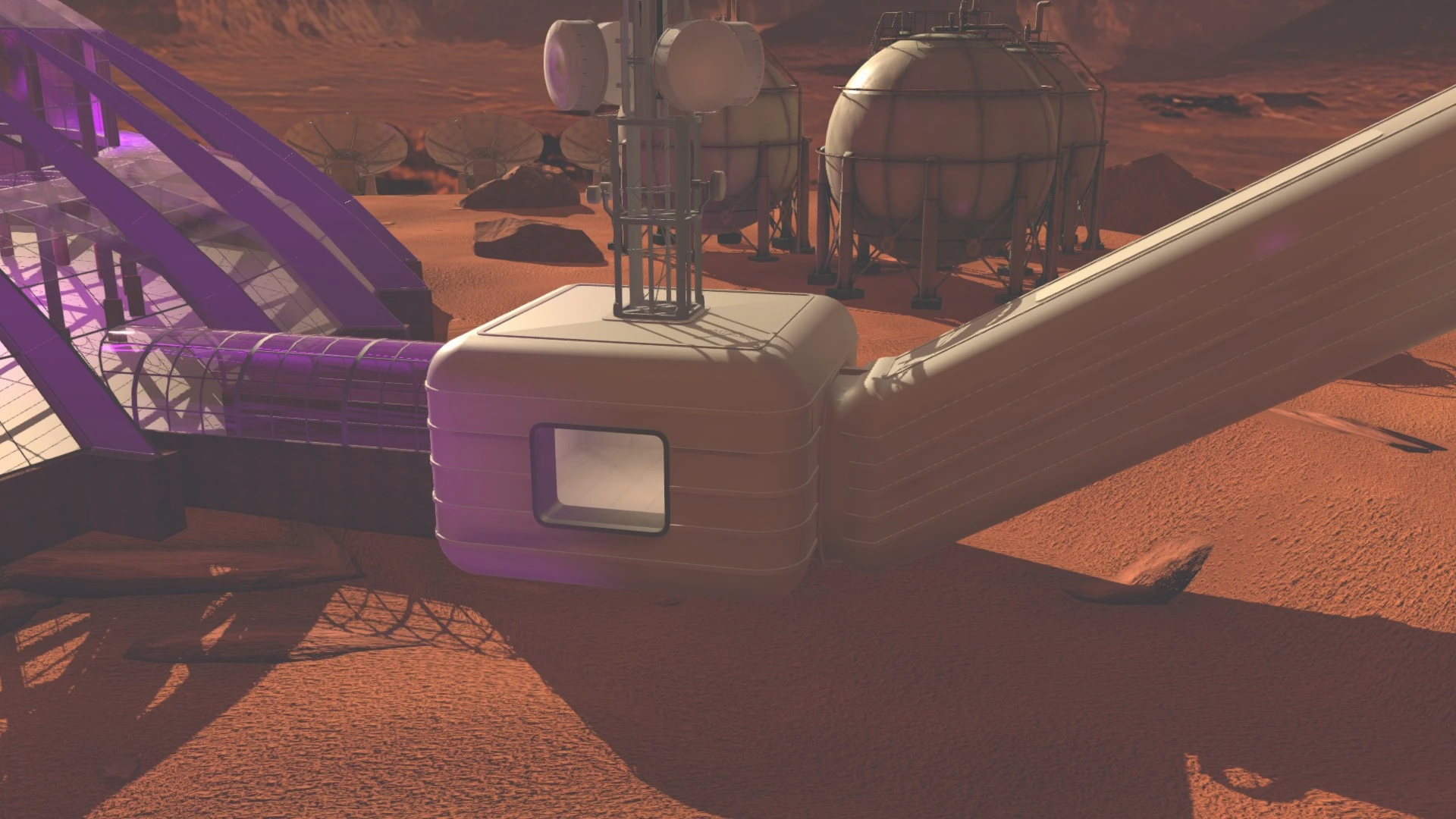

The primary operational level of the facility is elevated approximately 6.56 meters above ground level.

This elevation serves multiple functional purposes: protection from dust accumulation, improved thermal stability, simplified routing of infrastructure, and a clear separation between operational and environmental layers.

The open space below the facility enables maintenance access, modular expansion, protected cabling, fluid routing and future structural adaptation without interfering with active operations.

Structural Platforms and the 6.56 m Grid

The height of 6.56 meters is not arbitrary. It aligns with the internal structural grid and modular scaling logic used throughout the facility.

This clearance allows standardized container modules, pressure units, robotic systems and transport drones to operate beneath the facility without custom adaptations.

By standardizing vertical space, the facility avoids bespoke construction and supports long-term reconfiguration — a core zero-waste requirement.

Design Philosophy

The facility follows the same principles as Martian Micro devices: zero waste, modularity and functional clarity.

Every structural element must be repairable, reconfigurable or recyclable.

Nothing exists without a defined operational purpose.

Modular Structure and Sectors

The facility is divided into clearly defined sectors, each responsible for a specific operational domain.

This separation allows independent maintenance, upgrades and reconfiguration without impacting unrelated systems.

Operational Areas

The Martian Micro Research Facility is organized into clearly defined operational areas, each dedicated to a specific function within the closed-loop production and research system.

Core operational areas include:

- Broadcast Studio — internal documentation, monitoring and system observation.

- Development Area — software development, system configuration and device logic design.

- Maintenance & Infrastructure — power distribution, networking, environmental systems and facility maintenance.

- Recycling: Washing & Sorting — material preparation, separation and quality control for reuse.

- Recycling: Filament Production — processing of recycled material into usable filament for additive manufacturing.

- Additive Manufacturing Area — 3D printing of components, housings and modular structures.

- Storage & Repair — storage of components, spare parts and refurbishment of devices.

These areas are connected by a central corridor, forming the primary operational level of the facility.

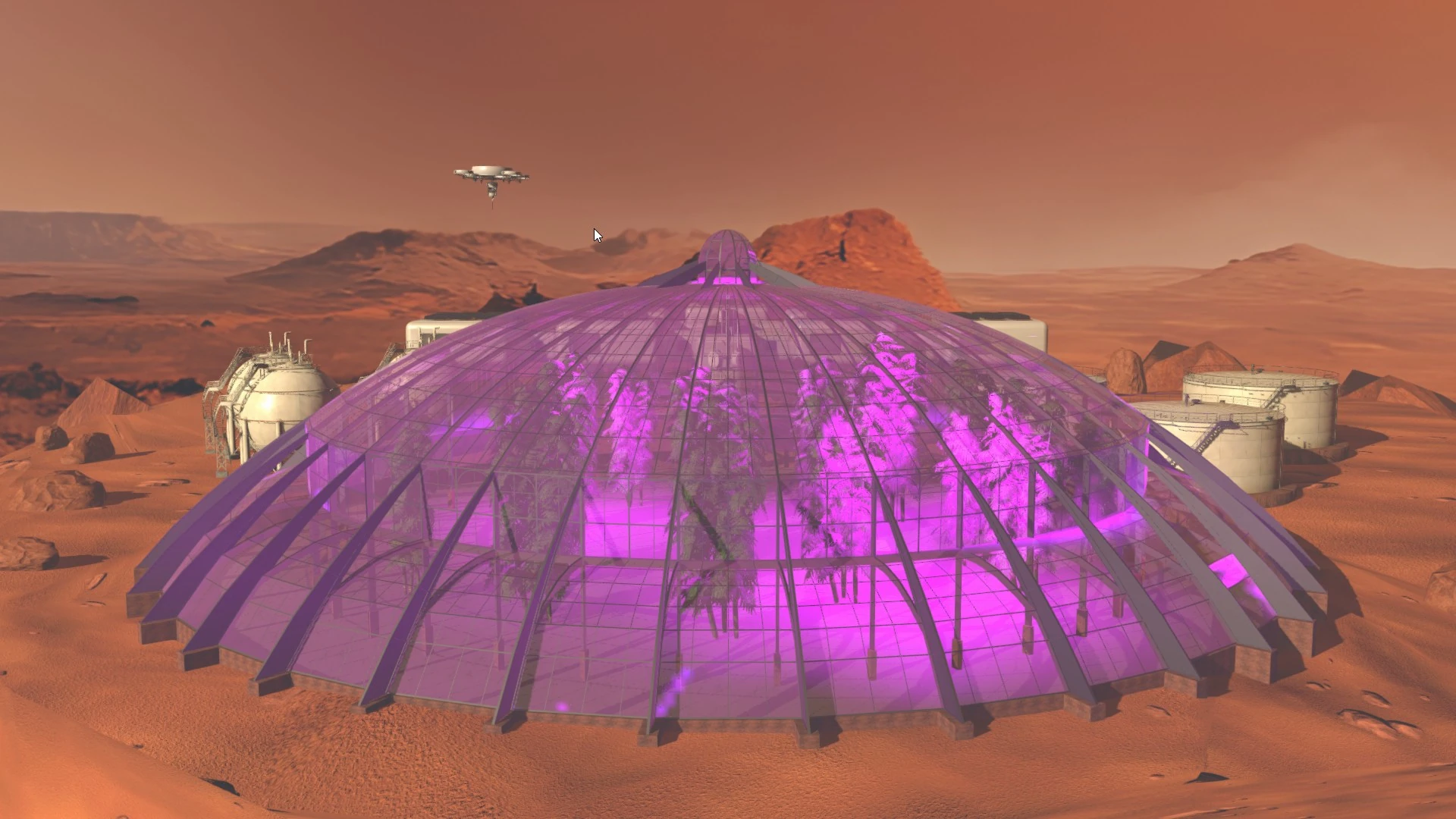

The BioDome

The BioDome is a protected biological research zone used for biomass-related experiments.

It is not a sealed, self-supporting glass habitat.

The dome functions as a protective enclosure over a modular internal area rather than as a pressurized living structure.

The outer ring of the dome forms a circular service corridor. The central area remains a flexible open space designed to accommodate modular, pressure-rated containers and experimental structures.

Current experiments focus on corn cultivation under artificial light to generate biomass used for PLA-based filament production.

This architectural approach allows the internal configuration of the BioDome to evolve over time without structural changes to the enclosure itself.

Human Quarters

The Human Quarters are located on an intermediate level below the main operational platform, approximately two meters above ground level.

This position places them closer to the BioDome and the primary external airlock systems, reducing transit distances for human personnel.

The Human Quarters are used for short-term stays by human operators during maintenance, inspection and oversight tasks.

They are the only areas of the facility designed with explicit consideration for human comfort.

All other areas of the facility are optimized for autonomous systems. Human presence outside the Human Quarters is permitted only to meet safety and regulatory requirements.

The primary airlock for extravehicular activity is located adjacent to the Human Quarters.

Operational Consistency

The facility is engineered as a single, coherent operational system.

All components are designed to expose real system state without interpretive abstraction.

Monitoring and visualization are treated as operational tools, not representational layers.